The pathway to improvement leads through change

Change happens when employees actively participate.

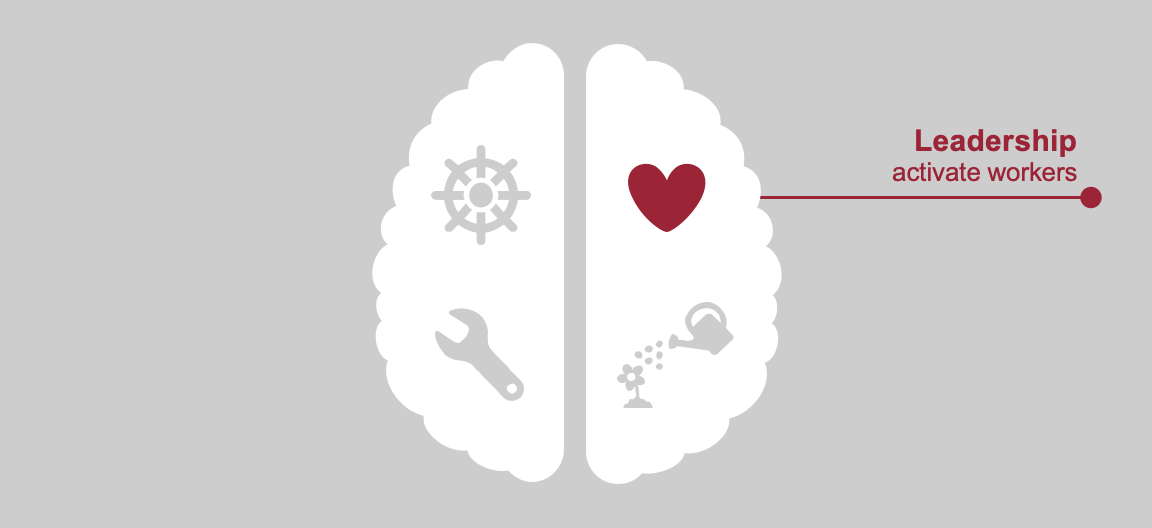

Lean reform, like continuous improvement activities, involves change. This represents a challenge for every company. For the lean journey, it is crucial to get the employees on board and to win them over for the transformation process; leadership is the decisive success factor here. In this respect, Japan has some unconventional approaches up its sleeve. Learn first-hand from top managers and the practical experience of their reforms ... more about our webinars

The decades of improvement activities in Japanese companies have provided valuable insights for management practice. For example:

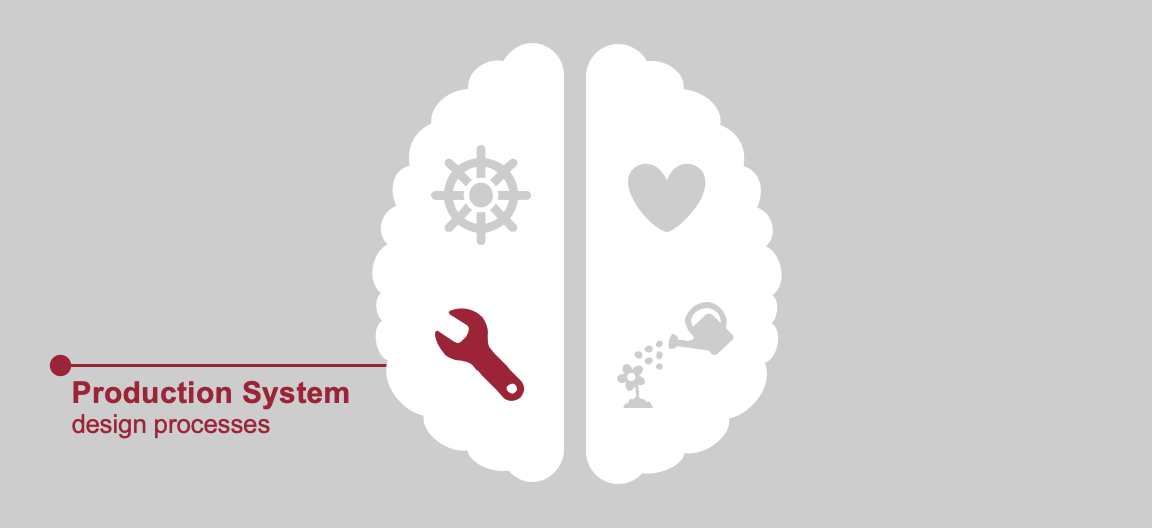

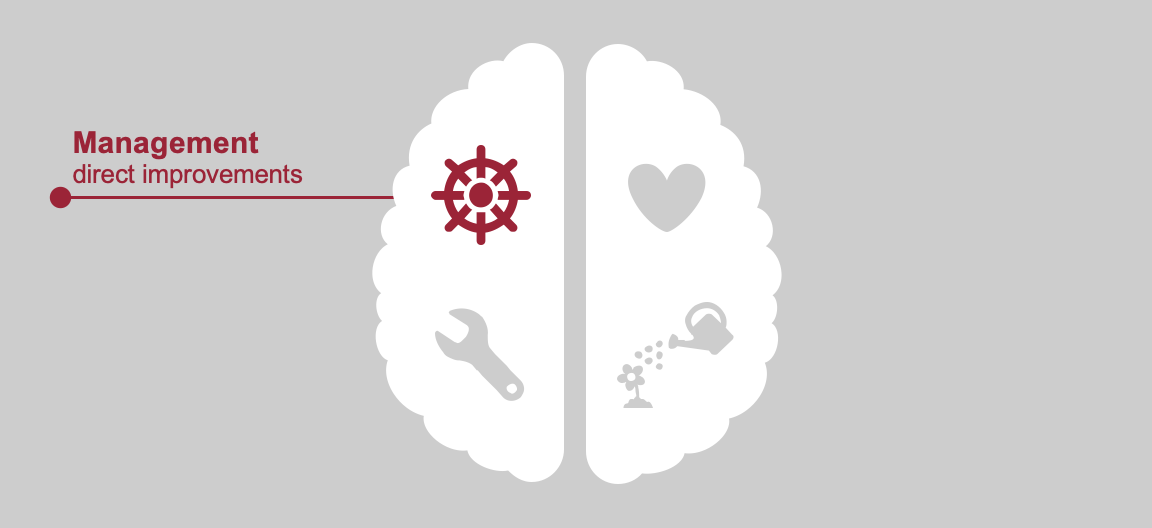

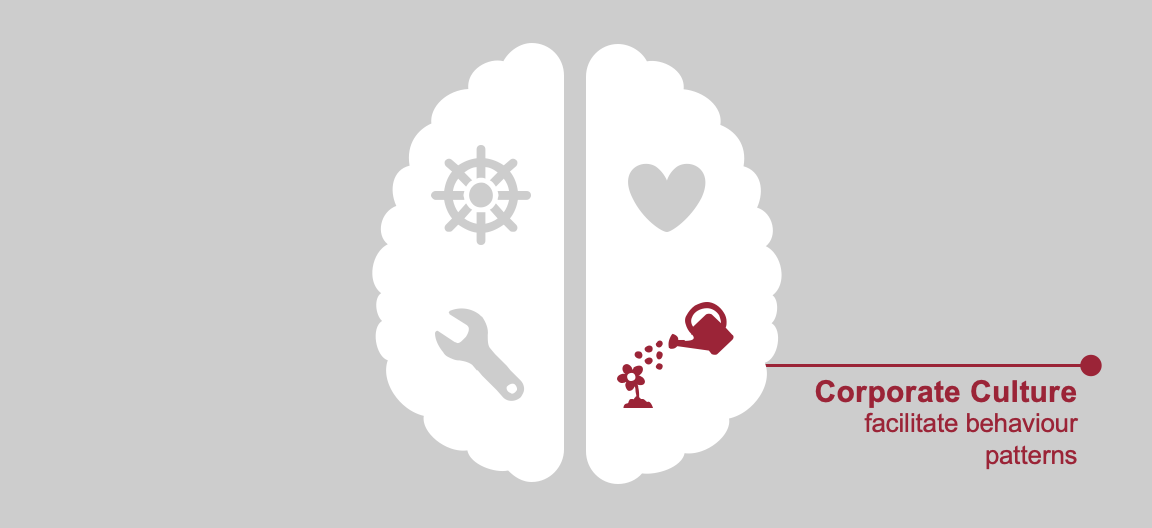

The ability for continuous improvement lies in the interaction between the four areas: production system, management, leadership, and corporate culture (see image above).

We have a tendency to pursue improvement measures top-down and concentrate on the kaizen tools. Japanese kaizen companies, on the other hand, conduct their activities in a balanced mix of top-down, bottom-up, left-brain and right-brain approaches. This can be experienced during company visits in Japan …

...

more about our Learning Journeys

more infos shortly